Encountering guides

Early guides were susceptible to seizure and abrasion marks being caused, and often the steel would overshoot the guides or not enter the mill correctly, causing problems with efficiency and quality. After static guides were replaced with Roller Guide for rolling mill, such problems were resolved, and efficiency and quality improved dramatically. Here are some products developed jointly with major steel manufacturers to deal with the problems they faced.

Product introduction

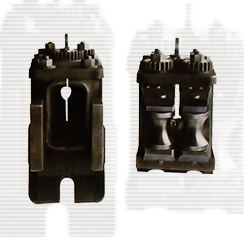

EPN25

- Wire rod guide

- The use of special cast-steel roller holders helps produce high levels of elasticity

- The gap between the roller surfaces is a central-dividing- type mechanism that can be adjusted using a ratchet

- The mechanism enables rollers to be adjusted on just one side

EPPD70PCG

- Maintains a fixed cohesion strength at the tip, middle and tail section of the steel

- Enables uniform guide adjustment by means of cohesion strength monitoring at the time of milling

- Adjustment of the gap between the roller surfaces can be controlled remotely

- External input signals such as HMD and the like are unnecessary

FERD250PRC

- Width adjustable roller guide for flatbar

- Two sets (a total of 4) rollers guide the steel

- Adjustment of the gap between the roller surfaces

Kotobuki Sangyo roller guides are now indispensable in the world-renowned Japanese steel industry, as a tool vital for the manufacture of high quality, high value-added products.

Roller guide, environment development, please feel free to contact us to the other.